How Precision CNC Machining Helps Startups Scale Manufacturing

Startups often struggle to find the right manufacturers to turn ideas into tangible products. How does precision CNC machining help, and what's the process?

OH, UNITED STATES, January 15, 2026 /EINPresswire.com/ -- Small businesses win with CNC machining when they use it to scale repeatability first—then scale volume. One early decision is how to build prototypes and early production parts. Hard tooling can slow progress. Industry guidance notes that a metal injection mold typically takes four to eight weeks to produce and can cost about $2,000 to $100,000+, depending on complexity. By contrast, some manufacturers list standard CNC machining lead times of about three business days, with faster options on eligible parts.

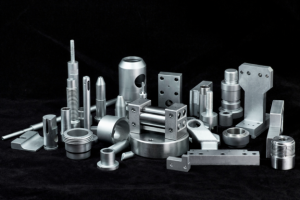

CNC (computer numerical control) machining makes parts by removing material from metal or plastic stock with programmable tools. It is common in prototyping and early production. It is often used when designs still change, but performance must be tested in real materials.

Why CNC Machining Is Helpful for Start-Up Businesses

Teams often choose CNC machining for these reasons:

※Short iteration loops. Parts can follow CAD changes without new tooling.

※Real material testing. Teams can validate strength, heat, wear, and corrosion behavior.

※Controlled fits. Threads, sealing faces, and mating interfaces can be produced to defined limits.

※Low-volume runs. The same drawings can support prototypes and early batches.

When CNC Machining Is Not The Best First Choice

CNC machining is not ideal for every case:

※Complex internal channels may be faster with additive methods in the concept phase.

※Very large parts may require specialized capacity and longer queues.

Comparing Common Manufacturing Methods

To help business owners decide when to switch from prototyping to production, here are the most common manufacturing paths:

1-3D Printing (Additive)

※Best used for: Visual concepts; complex internal shapes

※Material strength: ~70–80% of final strength

※Setup investment: Low

※Repeatability: Lower

※Typical lead time: 1–2 days

2-CNC Machining (Subtractive)

※Best used for: Functional testing; low-to-mid volume

※Material strength: 100% real material strength

※Setup investment: Moderate (programming time)

※Repeatability: High (precision within 0.01 mm)

※Typical lead time: 3–5 days

3-Injection Molding (Forming)

※Best used for: High-volume mass production

※Material strength: 100% real material strength

※Setup investment: High (mold tooling costs)

※Repeatability: High (once mold is perfected)

※Typical lead time: 4–8 weeks

High-Performance Applications in Key Industries

While CNC has limitations with internal geometry, it excels in sectors where material integrity is non-negotiable. For hardware startups, safety and tolerance are often critical.

Automotive Applications

For instance, the automotive and aftermarket sectors rely heavily on this technology. CNC motorcycle parts manufacturers use machining to craft custom engine components, brackets, and durable upgrades. In these scenarios, parts must withstand high vibration and heat—conditions where typical 3D-printed prototypes might fail.

Medical Applications

Similarly, medical device startups use CNC to mill biocompatible materials, ensuring the prototype matches the final product’s mechanical properties exactly.

How to Succeed With Professional CNC Services

A professional CNC services supplier provides hands-on support at key stages, easing common startup challenges:

※Design review: Early DFM input helps refine parts for easier production, saving time on revisions.

※Prototyping: Quick, accurate parts allow real-world testing and faster iterations.

※Production scaling: Reliable transition to higher volumes keeps quality steady and costs manageable.

※Quality assurance: Thorough checks catch issues early, giving founders confidence in every batch.

From Rapid Prototyping to Production

The peak sales season each year is short, and even a small, poor quality part can impact the overall project timeline. For companies launching new projects, it's crucial to have a CNC machining rapid prototyping supplier that can provide fast prototyping and DFM (Design for Manufacturability) tips during the process to improve part feasibility.

Sure, the speed and quality of this transition depend on the manufacturer. Experienced providers, such as Tuofa CNC Rapid Prototyping, understand these critical pivot points. They help startups navigate the gap between a digital CAD file and a physical, market-ready product.

Ultimately, small businesses succeed by validating their designs in real materials quickly. By leveraging CNC machining, they reduce technical risk and accelerate their time to market, turning a concept into a scalable reality.

Tuofa Team

Tuofa CNC Machining

+86 13713980135

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.