Metal Powder Market Sales Expected to Expand from USD 9.0 Billion in 2023 to USD 14.9 Billion by 2034 - Report by TMR

Metal Powder Market Expected to Hit USD 14.9 Billion by 2034 Driven by Additive Manufacturing Demand - TMR Analysis

Metal Powder Market Size Forecast to USD 14.9 Billion by 2034 with Growing Demand from Automotive and Aerospace – TMR Analysis”

WILMINGTON, DE, UNITED STATES, August 19, 2025 /EINPresswire.com/ -- Metal Powder Market Report (Outlook 2034)— Trending Report by TMR

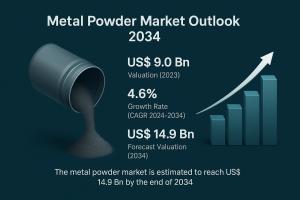

The global metal powder market is positioned for steady growth on the back of expanding powder metallurgy (PM) applications, fast-rising additive manufacturing (AM) adoption, and demand for lightweight, high-performance components across automotive, aerospace, medical, and industrial sectors. The industry was valued at US$ 9.0 Billion in 2023 and is estimated to grow at a CAGR of 4.6% from 2024 to 2034, reaching US$ 14.9 Billion by 2034.

Increasing use of press-and-sinter PM parts, accelerating metal AM for prototypes and series production, and advances in gas/water atomization, plasma spheroidization, and recycling are broadening use cases while improving quality, yield, and sustainability.

Don't miss out on the latest market intelligence. Get your sample report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=69533

Market Overview

Metal powders—ferrous and non-ferrous—enable near-net-shape manufacturing with excellent material utilization and design freedom. From automotive gears and structural parts made via PM to titanium and nickel superalloy powders for 3D-printed aerospace and medical implants, users benefit from weight reduction, shortened lead times, and cost-effective complexity. New circular-economy initiatives (scrap-to-powder, closed-loop reclaim) are helping stabilize supply and reduce environmental impact.

Analyst Viewpoint

Analysts view metal powders as a strategic enabler of next-gen manufacturing. The dual engine of growth—mature PM (cost, scale) and scaling AM (complexity, customization)—will keep demand resilient through 2034. Competitive advantage will hinge on powder consistency (flowability, PSD, oxygen control), application engineering, and quality certifications for highly regulated sectors.

Analysis of Key Players

Leading companies focus on capacity expansions, atomization technology upgrades, application partnerships, and sustainability:

• BASF SE

• Sandvik AB

• GKN Plc

• Rio Tinto

• Hoganas AB

• JFE Holding, Inc.

• Vale S.A.

• Alcoa Corporation

• Laiwu Iron & Steel Group Powder Metallurgy Co., Ltd

• GGP Metal Powder AG

• Metal Powder Company Limited

• Other Leading Companies

(Company coverage typically includes overview, product portfolio, grades & alloys, certifications, financials, strategic moves, and recent expansions.)

Market Developments

• May 2021 – Rio Tinto developed a steel powder for additive manufacturing at its RTFT metallurgical facility in Canada. Produced using water atomization technology, this powder delivers enhanced mechanical properties, making it highly suitable for 3D-printed metal components.

• April 2024 – AMAZEMET advanced metal additive manufacturing by implementing the Siemens Xcelerator portfolio, enabling scale-up, engineering optimization, and seamless service documentation across devices. Its flagship product, RePowder, an ultrasonic atomizer, allows the creation of metal powders from a wide range of alloys and feedstock forms, expanding the flexibility of metal powder applications.

Each of these companies has been profiled in the metal powder market research report based on parameters such as company overview, financial performance, business strategies, product portfolio, business segments, and recent developments.

Key Strategies by Market Players

• AM-Grade Portfolio Expansion: Ti-6Al-4V, Inconel, CoCr, maraging steel, aluminum alloys tailored for L-PBF, EBM, DED, and Binder Jetting.

• Process Integration & Partnerships: Powder suppliers partnering with OEMs, service bureaus, and end-users for application co-development and qualification.

• Quality & Certification: Tight PSD control, low oxygen/nitrogen, ISO/AS9100/ISO 13485 compliance for aerospace/medical.

• Sustainability & Recycling: Scrap valorization, renewable energy in atomization, powder reclamation for AM.

• Regional Capacity Build-out: New lines near demand hubs in North America, Europe, and Asia to cut lead times and logistics risk.

📌 Detailed strategy mapping is available in the sample report copy - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=69533

Key Growth Drivers

1. Automotive Electrification & Lightweighting: Copper, aluminum, and soft-magnetic powders for e-motors, gears, and thermal management.

2. Aerospace & Defense Demand: High-temperature nickel/titanium powders for complex, weight-critical parts.

3. Rise of Metal AM in Production: Design freedom, part consolidation, and rapid iteration moving beyond prototyping.

4. Cost & Material Efficiency: PM delivers near-net shape with minimal waste vs. subtractive routes.

5. Medical & Dental Applications: Patient-specific implants and instruments needing certified, high-purity powders.

6. Industrial & Energy: Wear-resistant overlays, thermal spray, filtration media, hydrogen & battery components.

Market Segmentation Snapshot

By Material

• Ferrous: Stainless steel, low-alloy steel, tool steel, soft-magnetic iron

• Non-Ferrous: Aluminum, titanium, nickel & superalloys, copper, cobalt, precious metals

By Manufacturing Process / Use

• Press & Sinter PM

• Metal Injection Molding (MIM)

• Additive Manufacturing (L-PBF, EBM, DED, Binder Jetting)

• Hot Isostatic Pressing (HIP)

• Thermal Spray / Brazing / Welding

By End-use Industry

• Automotive & Transportation

• Aerospace & Defense

• Medical & Dental

• Industrial Machinery & Tools

• Energy (conventional & renewable)

• Consumer & Electronics

Regional Description

• North America: Strong aerospace/medical certification base; active AM adoption and localized powder supply.

• Europe: Leadership in specialty alloys, sustainability, and quality standards; robust aerospace & industrial clusters.

• Asia Pacific: Fastest growth; automotive volume, electronics, and expanding AM ecosystems in China, Japan, South Korea, and India.

• Latin America & Middle East: Gradual uptake via industrial, energy, and aviation value chains; growing interest in localized AM hubs.

Key Takeaways for Stakeholders

• Producers: Invest in high-purity AM powders, advanced atomization, and circular material flows; deepen application engineering.

• OEMs & Tier Suppliers: Co-design parts for PM/AM; qualify powders and processes early to de-risk scale-up.

• Investors: Opportunities in binder-jet production lines, recycling/reclaim tech, and regional powder hubs.

• Distributors & Partners: Build just-in-time networks with traceability and powder handling expertise.

Why Buy This Report?

✅ End-to-end coverage of materials, processes, and end-markets

✅ Forecasts to 2034 with scenario analysis and risk factors

✅ Strategic benchmarking of leading powder producers and AM ecosystems

✅ Sustainability and certification roadmaps for regulated sectors

👉 Purchase the full report now @ https://www.transparencymarketresearch.com/checkout.php?rep_id=69533<ype=S

Future Outlook: Toward Digital, Green, and Qualified Powders by 2034

Expect digitally traced powders (lot-level data, in-process monitoring), broader binder-jet series production, and net-zero pathways (renewable energy atomization, reclaimed feedstocks). Qualification frameworks will shorten time-to-production in aerospace/medical, while automotive electrification unlocks new powder grades for magnetic and thermal applications.

Conclusion

Metal powders are the material backbone of near-net-shape and additive manufacturing. As quality, sustainability, and application know-how advance in tandem, the market is set to expand from US$ 9.0 Bn (2023) to US$ 14.9 Bn by 2034 at a 4.6% CAGR, enabling lighter, smarter, and more efficient products across industries.

More Trending Research Reports-

• Powder Metallurgy Market - https://www.transparencymarketresearch.com/powder-metallurgy-industry.html

• Powder Metallurgy Component Market - https://www.transparencymarketresearch.com/powder-metallurgy-components-market.html

• Biocides (Halogen Compounds, Metallic Compounds, Organosulfurs, Organic Acids, Phenolic, Nitrogen and Other) Market - https://www.transparencymarketresearch.com/global-biocides-market.html

• Inorganic Metal Finishing Market - https://www.transparencymarketresearch.com/inorganic-metal-finishing-processes.html

• Rare Earth Metals Market - https://www.transparencymarketresearch.com/rare-earths.html

• Nanocomposites (Carbon Nanotubes, Polymer Metal Fiber, Nanofibers, Graphene, Nanoplatelet and Others) Market - https://www.transparencymarketresearch.com/nanocomposites-market.html

• Base Metal Mining Market - https://www.transparencymarketresearch.com/base-metal-mining-market.html

• Recycled Metal Market - https://www.transparencymarketresearch.com/metal-recycling-market.html

• Silicon Metal Market - https://www.transparencymarketresearch.com/silicon-metal-market.html

• Metal Cans Market - https://www.transparencymarketresearch.com/metal-cans-market.html

• Metal Matrix Composites (MMC) Market - https://www.transparencymarketresearch.com/metal-matrix-composites.html

• Metal and Ceramic Injection Molding Market - https://www.transparencymarketresearch.com/metal-ceramic-injection-molding.html

• Metal Cleaning Equipment Market - https://www.transparencymarketresearch.com/metal-cleaning-equipment-market.html

• Metalworking Fluids Market - https://www.transparencymarketresearch.com/metalworking-fluids-market.html

• Metal Fabrication Market - https://www.transparencymarketresearch.com/metal-fabrication-market.html

About Us Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. The firm scrutinizes factors shaping the dynamics of demand in various markets. The insights and perspectives on the markets evaluate opportunities in various segments. The opportunities in the segments based on source, application, demographics, sales channel, and end-use are analysed, which will determine growth in the markets over the next decade.

Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers, made possible by experienced teams of Analysts, Researchers, and Consultants. The proprietary data sources and various tools & techniques we use always reflect the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in all of its business reports.

Contact Us

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Blog: https://tmrblog.com

Email: sales@transparencymarketresearch.com

Atil Chaudhari

Transparency Market Research Inc.

+ +1 518-618-1030

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.